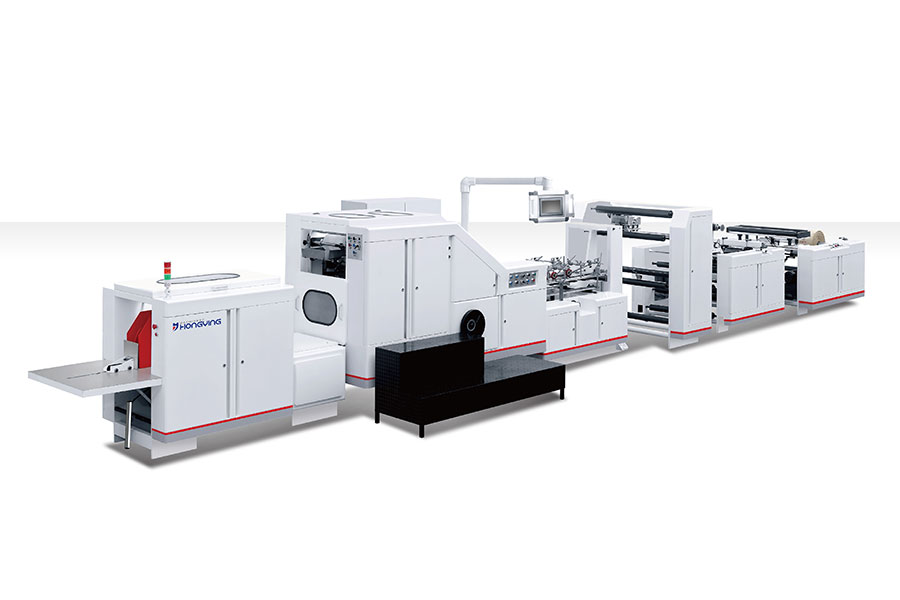

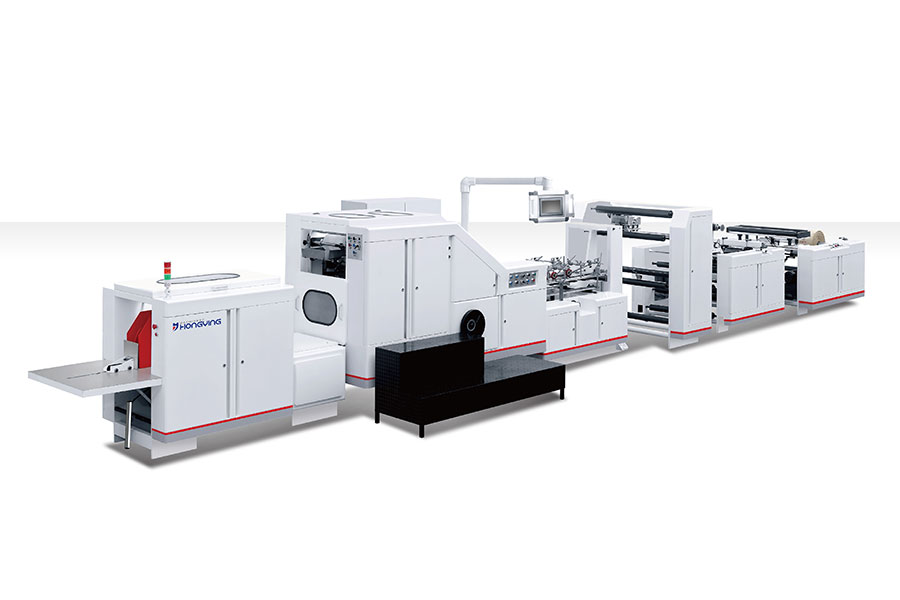

SBR-290 Adjustable roll square bottom paper bag making machine, it has the advantage of fast making, high production efficiency ,large adjustment range, comprehensive domestic inadequate of similar products, then to improve the new equipment.

Paper bag making machine make the primary color or printed roll paper to glue on the side. Folded into a tube, glue on the bottom, bag bottom forming and export bags.

Paper bag machinery make is controlled by computer central control system, touch screen display, the servo motor control the length of paper bags, it can produce a variety of sizes paper bags,the fastest can reach to 220 pcs/min, it’s greatly reducing the labor costs.

Paper bag making machinery is the best choice for producing square bottom paper bags.

SBR-290 Adjustable roll square bottom paper bag machine

1. Material feeding using hydraulic lift structure, unwinding using automatic tension control.

2. Side glue using the auto gluing system.

3. Correction using the pausource from Taiwan

4. Paper tube forming device include thumb-cut function

5. Automatic shutdown, when it run out of material

6. All of center clip, drum clamps and drum machines are suing spider synchronous adjustment mechanical design, it can significantly reduce the adjustment time to replace the size.

7. With Germany SICK photoelectric, accurately tracking the printed materials

8. Equipped with automatic lubrucation supply system, stoppage alarm system.

|

MODEL |

SBR-290 |

|

WIDTH OF PAPER |

320-930 MM |

|

CUTTING LENGTH |

270-500 MM |

|

WIDTH OF PAPER BAG |

100-280 MM |

|

LENGTH OF PAPER BAG |

225-460 MM |

|

WIDTH OF BAG BOTTOM |

60-160 MM |

|

PAPER WEIGHT |

60-160 GSM |

|

MAX. SPEED |

180 PCS/MIN |

|

SIZE OF MACHINE |

8600*2200*1800 MM |

|

TOTAL WEIGHT |

6500 KG |

|

TOTAL POWER |

13 KW |